After nearly 4 years of designing, Bellatrix is the most complex and the best sounding speaker I’ve built so far.

THE MAKING OF BELLATRIX

The adventure with Bellatrix began in 2017. After the success of the third generation Proxima and Electra, which were well-received by the market, it was time for something completely new and better in every aspect.

For several months, the search for a new shape took place, one that would be instantly recognizable, different from the competition, and at the same time reminiscent of the “flat boxes” of Proxima and Electra.

However, a larger volume was needed to accommodate two bass drivers. After constructing several prototypes, initially made of cardboard, Bellatrix acquired an octagonal cross-section. The shape is further inclined towards the rear, with angled top and bottom edges, and its depth is still smaller than its width.

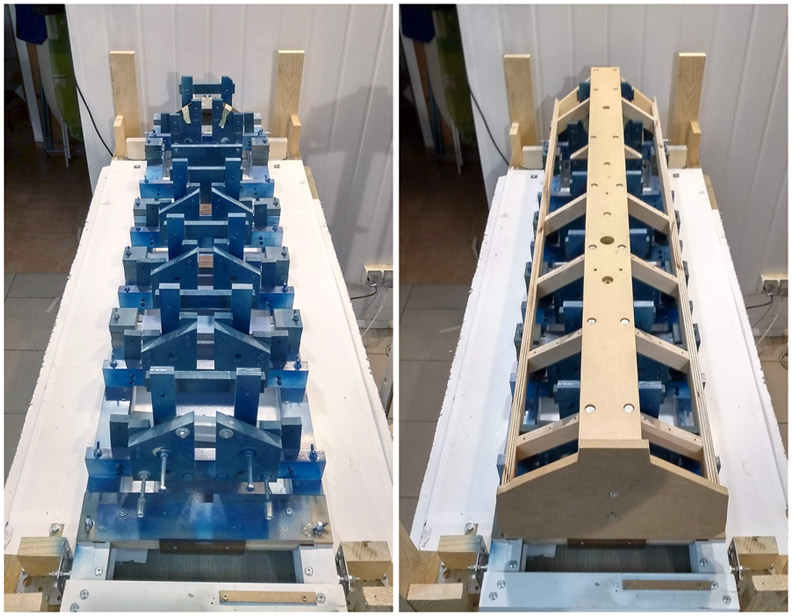

Despite the complexity of the cabinet shape and the numerous different cutting angles, templates were created for each wooden and metal component, and the internal frame of the cabinet is constructed on a specially built assembly table. The development of templates and cutting technology took almost 9 months to achieve the desired precision of the components, with tolerances below 0.3mm. The wooden elements of Bellatrix are crafted using traditional methods, without the use of CNC machines.

However, the visual aspect is only a part of the cabinet design. What is more important lies inside. The cabinet is vented downwards, but it is not a typical bass-reflex design. Bellatrix is divided by partitions into several interconnected chambers that together form a diffusing-damping resonant system, which is an interpretation of the TQWT (tapered quarter-wave tube) enclosure.

Creating such a cabinet required the construction of a special prototype that could be opened, adjusted, and subjected to tests. This allowed each chamber to be tested during listening sessions and to examine how different damping materials affect the midrange and bass. The well-established CRCdesign technology used in Divine Acoustics was given a new, more complex and improved form during the design of Bellatrix.

The result of over a year of work is a cabinet that does not contain loose damping material inside. It has a series of reinforcements, cross-braces, and ribs, additionally strengthened by a steel lattice that connects the side walls and disperses vibrations along the height dimension. However, it is not a cabinet that completely eliminates vibrations. The design solutions employed allow some of its walls to remain “live” for vibrations. Appropriate amount of specifically chosen diffusing material is placed in strictly defined locations. The finishing panels also serve a damping role.

The start of work on Bellatrix coincided with the introduction of a new series of speakers by Eton. After discussions with an Eton representative, I decided to order several types of new speakers for testing. What impressed me about them was the construction of the diaphragm, which used cellulose in a modern yet somewhat vintage manner. The diaphragms are uncoated, just as they were made many years ago, but thanks to numerous embossings, they achieve a very high stiffness that was previously unattainable.

After making necessary modifications such as precise damping of the speaker baskets (Basket Accurate Dampening) and mounting the speakers on isolation pads that separate them from the cabinet, the 7-inch Eton Orchestra series speakers started reproducing the bass and midrange of Bellatrix.

Completing the Eton speakers required a high-quality tweeter. Choosing one was not easy and took a long time.

The natural “companion” to cellulose diaphragms in midrange drivers is a tweeter with a silk diaphragm. Both materials are natural and complement each other excellently. There are plenty of tweeters on the market with silk diaphragms, but there were only a few that I could use for this project.

The first parameter taken into account was impedance. Bellatrix is a 2.5-way system, nominally 4 ohms in a wide range. Therefore, the tweeter had to be 4 ohms to provide a more “predictable” impedance for amplifiers working in conjunction with Bellatrix. Thus, all the 8-ohm and 6-ohm tweeters were eliminated.

The second criterion for selection was the efficiency of the tweeter. It couldn’t be too high because the midrange tones would not exceed 87dB/1W/1m efficiency. It seems that loudspeaker manufacturers, for some reason, participate in a race to create speakers with the highest possible efficiency, even at the expense of sound quality. The market is flooded with tweeters boasting an efficiency of 93dB, 95dB, and higher. But how can one use such a tweeter with a bass driver that doesn’t reach 90 decibels of efficiency? Dampen it excessively? Divide the voltage in the crossover? Sacrifice microdynamics? Therefore, all tweeters with an efficiency above 90dB were eliminated.

Finally, the choice fell on the ring radiator Scan-Speak Illuminator tweeter with all its advanced technologies. I chose the version with a large damping chamber behind the diaphragm, very low resonance, and the desired efficiency below 90dB. Why not the more popular version with a “cloverleaf” front? Precisely because of its higher efficiency.

For years, Divine Acoustics has used the TMI (Tweeter Multilayer Isolation) system, which involves isolating the tweeter from the main cabinet structure. Due to the small front surface of the Scan-Speak tweeter, the traditional set of pads made of various materials had to undergo a transformation. After many months of experimentation with different materials and configurations, a new technology for using hard materials was developed – CeraGem. The tweeter has its own separate subchassis that integrates a system of multiple damping layers. The same technology was used in our Kepler vibrations absorbing feet.

Bellatrix cabinets have a meticulously damped separate chamber in which the tweeter is mounted along with its entire damping system.

What kind of crossover should be used to precisely control the carefully prepared drivers and not compromise the efforts put into the cabinet design? It should definitely be extremely precise. How much time needs to be devoted to designing it? As much as necessary! Over the years, Divine Acoustics has used crossovers of various orders, which became more accurate as the development progressed. Over time, the SGP (Single Ground Point) and RFpath (Voltage Divider Elimination) systems were developed to further improve precision.

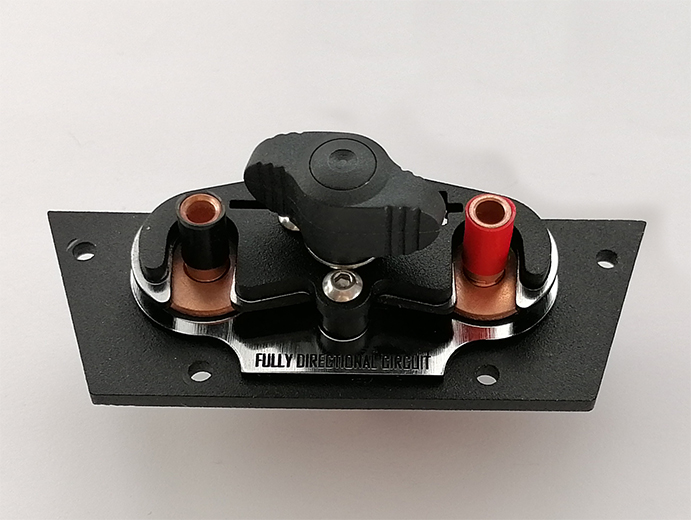

However, Bellatrix required a reorganization of the entire crossover scheme, determining the best slopes for a 2.5-way system, analyzing the influence of different crossover components on individual sound characteristics, and understanding their interdependencies. During the development of the Bellatrix crossovers, new design and assembly technologies were developed to ensure sound quality and repeatability in the construction of subsequent units: ESM (Energy Storage Management) and FDC (Fully Directional Circuit).

Explore our technologies:

Ultimately, despite the use of 1st and 2nd-order filters, the Bellatrix crossover contains 51 components mounted point-to-point, double-sided, on a board without traces. The planning of the single ground point alone took several months, and the integration of Scan-Speak and Eton drivers was the result of over a year of listening sessions and hundreds of micro-adjustments. To create speakers of very high quality, one must truly devote a lot of time to them.

The crossover is mounted in its separate enclosure, and during assembly, over 200 measurement points are checked according to a checklist.

Capacitors used are Miflex: copper KFPM and polypropylene MKP-14, as well as Jantzen Audio: Alumen, Z-Superior, and Z-Standard. The capacitors are combined in packages to achieve the highest precision of the required capacitance, and each package consists of at least two types of capacitors that complement each other in terms of sound.

The coils are prepared with pharmaceutical precision. They are weighed, measured with the highest available accuracy, and insulated with cotton to eliminate RFI/EMI interference.

Resistors used are non-inductive Superes with 1% accuracy, additionally matched with precise metal film resistors to achieve highly accurate and repeatable resistance.