At Divine Acoustics, we take the design process very seriously. We do not seta a predetermined duration for it either. Each project is only put into production when we are absolutely certain that we have done everything to make it sound its best.

Throughout the design process, we conduct numerous tests, and even the slightest change in sound quality does not escape our attention. None of the design elements are left to chance.

For over a decade, we have been developing and implementing unprecedented technologies not found in other manufacturers, all aimed at acheving the most faithfull sound reproduction in our speakers and accessories.

At Divine Acoustics advanced engineering serves the beauty of music.

Divine Acoustics Introduces CeraGem Technology! For many months in our laboratory we tested the properties of various materials and their influence on the sound of an audio system. We combined various types of materials – metals and their alloys, minerals, ceramics, hard and soft materials – we tested their various configurations. The result of these works is a multi-layer layout that very effectively disperses, accumulates and suppresses vibrations, and thus has a positive effect on the operation of the audio system – from the source, through the amplifier, to the loudspeaker set.

CeraGem technology combines the advantages of the correct combination of hard materials – ceramic sinter, precious stones with a repeatable crystal structure and various metals and their compounds.

CeraGem is our proprietary solution and does not replicate the approaches used by other companies that combat vibrations using ceramic balls, soft spacers, magnets or bearings.

We used CeraGem technology in our Kepler anti-vibration feet and in the construction of the internal tweeter subchassis of our new flagship Bellatrix speakers.

The Divine Acoustics loudspeaker enclosures are shapes in which form follows function, and the construction and finishing materials have been selected so as not only to create a beautiful form visually, but also so that their interaction creates the correct acoustic conditions.

Internal reinforcements and division into chambers prevent the formation of standing waves, and the multi-layer walls act as a dampening of unwanted resonances and vibrations. However, like many musical instruments that have resonance boxes that are “live” for vibration, the Divine Acoustics cabinets are also not damped in a way that all vibrations are suppressed at all costs.

We treat our cabinets as instruments and “tune them” taking into account the impact on the sound of specific materials used in their construction. Plywood, MDF, metals, plastics and finishing materials – all their combinations are designed similarly to anti-vibration systems – in order to positively influence the sound quality, disperse and dampen vibrations and unwanted resonances.

Our enclosures not only look good, but also work properly with the speakers mounted in them. They are designed for specific types of loudspeakers and take into account their parameters for optimal speaker-cabinet integration. The use of various types of materials for their construction and dampening is not a coincidence, but a part of the design process, many months of listening tests preceded by research.

CRCdesign technology integrates all our anti-vibration technologies: BAD, TMI and CeraGem. Although its implementation is time-consuming and labor-intensive, it turned out to be necessary to obtain a higher level of accuracy, refinement, delicacy and realism of the musical message.

Every loudspeaker generates vibrations during operation. They cause formation of resonances in the speaker basket and transfering them to the magnetic system. The vibrations of the magnetic system in turn cause distortions of the magnetic field in which the speaker coil moves. The effect of this is to increase the level of distortion, with the result that the sound of the speaker deteriorates, especially at higher volume levels.

In order to counteract this phenomenon, the BAD (Basket Accurate Dampening) system was created in the Divine Acoustics lab. It is a system that provides the speaker with comfortable working conditions. It lowers the level of vibrations transmitted from the diaphragm, through the speaker suspensions, to the magnetic system via the basket.

Appropriate modification of the speaker basket – change and partial extinction of its internal parasitic resonances – results in a significant improvement in the sound of the speakers themselves, even before mounting them in their housings!

The precise damping of the speaker baskets contributes to a significant improvement in the dynamics, stability of the sound stage and the sense of realism of the played recordings.

The BAD system is our proprietary solution. It fights against vibrations, the effect of which is simply overlooked in the designs of speakers from other companies. We use it in all our speaker designs.

The precision in reproducing of high frequencies is largely dependent on the conditions in which the tweeter works. Reducing the level of vibrations coming from the loudspeaker housing that reaches the tweeter coil significantly improves the quality of reproduction of the highest octaves of the acoustic spectrum.

During many hours of listening sessions in the Divine Acoustics studio, a system for effective isolation of the tweeter from the cabinet was developed. The appropriate combination of materials with different structures, densities and different dampening properties allows the tweeter to provide the best working conditions – it reduces the level of vibrations coming from the housing that reach the very delicate and light vibrating elements of the tweeters.

Thanks to the TMI damping system, treble sound smooth, natural and in great detail at both low and high volume levels. The precision in reproducing of high frequencies is largely dependent on the conditions in which the tweeter works. Reducing the level of vibrations coming from the loudspeaker housing that reaches the tweeter coil significantly improves the quality of reproduction of the highest octaves of the acoustic spectrum.

In a modern audio system with excellent parameters and extremely low distortion, the loudspeaker is still the weakest link. Due to its complex electromechanical structure, it introduces the most distortions to the sound. In order to lower them and for the music to be reproduced as faithfully as possible, the elements of the speakers, and in particular the crossovers, should be made with the greatest possible accuracy and full repeatability.

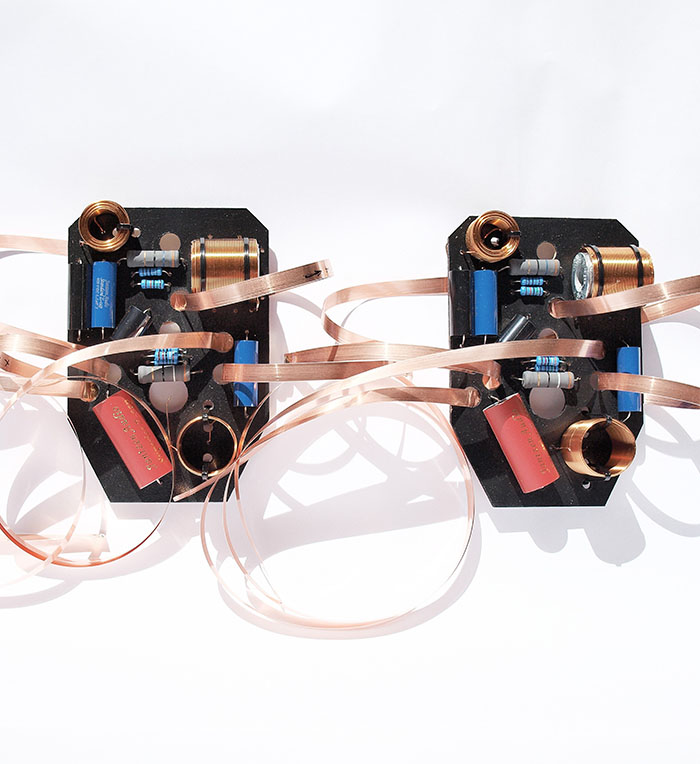

In the crossover circuits of Divine Acoustics, instead of a single capacitor of a certain capacity from the basic series, capacitor packets are used to obtain the desired total capacity with high accuracy and the smallest possible difference between the production units. In individual packages, capacitors from different manufacturers and different series are used to complement each other in sound.

With capacitances of the order of 0.01uF obtained after mergering 2 or 3 different capacitors, the order of charging and discharging the individual components of the package becomes of great importance for obtaining the desired sound. Incorrectly combined – they interfere with each other, make it difficult for the amplifier to properly drive the loudspeaker and cause sound degradation.

It turns out that even quite significant changes in sound quality caused only by differences in the connection of the same capacitors are immeasurable by the measuring equipment.

In order to obtain the desired sound of the loudspeakers, in particular high resolution, micro and macro dynamics and the ability to correctly determine the position of instruments in space, the operation of each of the capacitor packages is determined in the design process during long listening tests. Very careful direct assembly of the crossover components together with their appropriate prior preparation and measurements contributes to full repeatability of production and obtaining low distortions, and thus high-quality sound of the speakers.

Music accompanies us every day. Over the years, there have been many thousands of hours that we spent at Divine Acoustics listening to countless configurations of audio equipment.

During the listening sessions, we started to wonder why with bi-wiring connections we get different sonic results than with a single wiring, even when using 2 identical pairs of wires. There was one conclusion: the filters of individual speakers interfere with each other, and the double wiring moves the place where the filters are connected by the length of the wires, which, thanks to their resistance, reduces the level of interference affecting the crossovers.

Refining the filters in a way that makes them significantly less interfering has resulted in crossovers where you can no longer hear the difference between double and single wiring. We obtained the phase and time stability of the entire filter system.

From the first projects of Divine Acoustics that appeared on the market, we use single speaker terminals, and the crossovers are mounted on one board. We do not separate the crossover into sections and separate boards, we do not use double clamps connected with jumpers, as many other manufacturers do.

Moving on, we made many tests and built crossovers, the filters of which are the same according to the wiring diagram, but they differ in the arrangement of elements on the board and the way of their assembly. It turned out that the way the individual filter parts are connected is of fundamental importance for the sound quality. Even small changes in the connection of elements and how they are connected with the ground of the whole system influenced the sound. This is how we developed our SGP system – Single Ground Point.

The system assumes that all ground connections for the entire loudspeaker crossover electrical system and all grounding wires converge at one point. This prevents the formation of undesirable potential differences between the individual elements of the electric filters.

The use of one ground point significantly improves the sound of a loudspeaker set, improving its clarity, microdynamics and naturalness of the musical message.

A single ground point is one of the most important features of our crossovers. We use the SGP system in all our loudspeakers.

One of the most important elements of a loudspeaker system, and also the element that requires the most effort in designing, is the crossover. A properly selected electrical diagram, layout and arrangement of elements on the board, their quality, connection cables – all these factors affect the final sound of the set. Correctly selected values of the elements enforce the time and phase harmony of the loudspeakers of the set and affect its musicality, perceptible speed and punctuality.

The crossover system is not only about the division of the processing bandwidth and the phase arrangement of the speakers. It is also very important for the amplifier the distribution of the power consumed by the transducers. The correct division of the power flowing from the amplifier to the individual speakers allows for obtaining significant intensities of undistorted sound with full dynamic range and at the same time for reproducing the full range at very low volume levels. The crossover designed in this way makes it easier to drive the loudspeakers even to low-power amplifiers.

Thanks to a properly configured crossover the speakers work together to form a homogeneous whole, as if they became one transducer reproducing the entire frequency spectrum.

Over the years of gaining experience in designing speaker crossovers, the RFpath system has been developed at Divine Acoustics. The increasingly well-matched low and high-pass filters and the appropriate selection of loudspeaker efficiency in the design make it possible to completely resign from introducing voltage dividers to the crossover scheme.

Thanks to the RFpath system, the signal from the amplifier on its way to the tweeter flows only through high-class capacitors with precisely selected values. The signal path does not include unnecessary resistors or voltage dividers. All the other crossover elements for the tweeter, forming a 2nd order filter with impedance correction, are connected in parallel with the signal.

The use of this solution significantly improves the resolution and transparency of the reproduced high frequencies. The RFpath system is used in all Divine Acoustics loudspeakers.

The most important part of the design process at Divine Acoustics are intensive, many months of listening tests under controlled conditions. During the tests, parameters of elements used in the production of crossovers are also determined, which also affect the final sound effect, but cannot be measured with measuring equipment. One of them is the directivity of the signal flow.

In our loudspeakers, all elements in the crossovers and internal wiring are assembled with the correct directivity shown in listening tests.

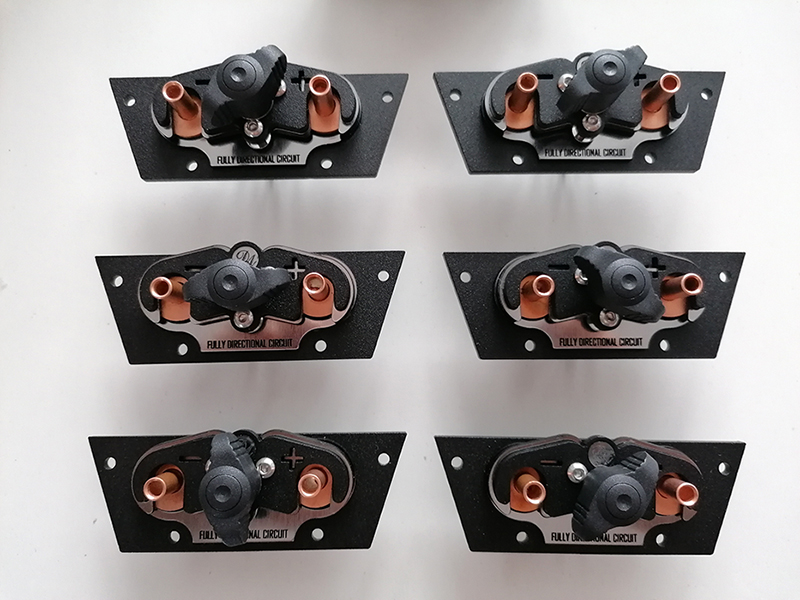

To ensure a fully directional signal path in our flagship Bellatrix speaker, Divine Acoustics has designed binding posts in which the signal is transmitted using pure uncoated copper elements with a listening-tested directivity. This provides a fully directional signal path from the loudspeaker terminals, through internal wiring and crossover components, to the driver coils.